IDE

Epteck's Contributions to IDE’s Vibration Isolation Systems

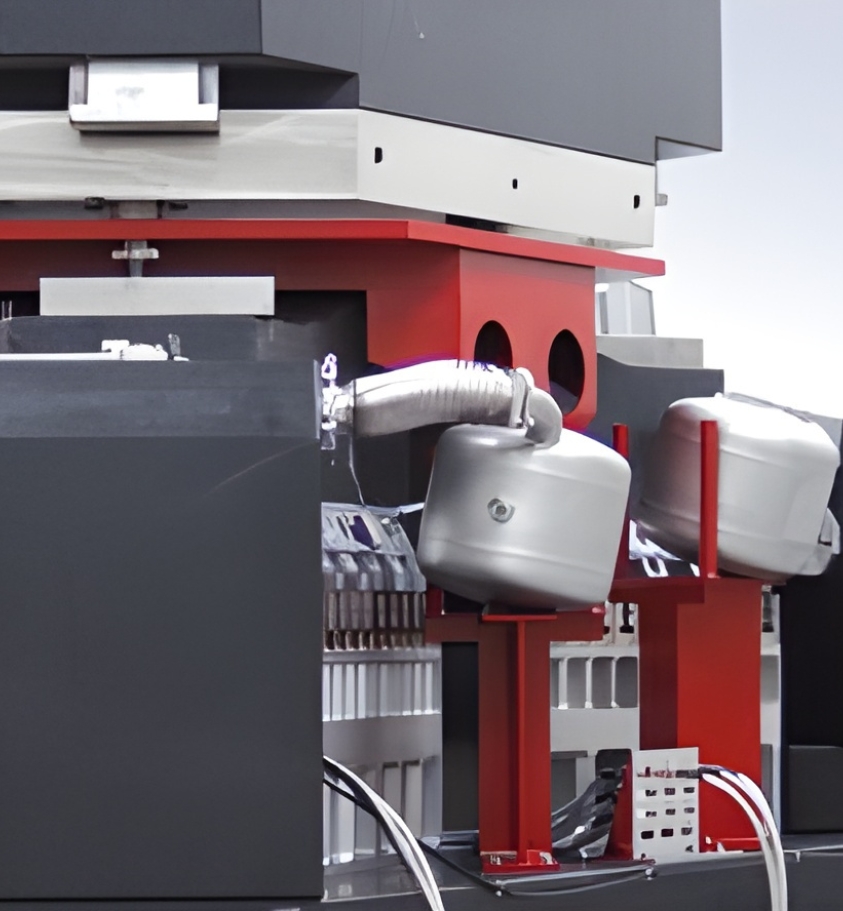

Epteck collaborated with Integrated Dynamics Engineering (IDE) on the development of a customized Board Support Package (BSP) for their Active Vibration Isolation system. The project involved utilizing technologies such as C, C++, Python, bootloaders, and the Yocto Project. Epteck’s expertise in real-time Linux, kernel development, and device tree customization allowed them to deliver a robust solution.

The primary objectives were to resolve hardware compatibility issues, reduce system latency, and enhance error detection, ensuring high system uptime and minimizing operational inefficiencies.

As a result of Epteck’s work, several measurable benefits were delivered to IDE, such as the completion of BSP development, and the resolution of hardware compatibility issues, ensuring 99% uptime in production.

- Services

- Client

- Location

- Project Duration

- Tech stack

- Development of Sleep Trainer

- IDE (Integrated Dynamics Engineering)

- Germany

- 2021 - July 2022

- C, C++, Python, bootloaders, Yocto Project, Unit Testing

What We Did to Solve the Problems

IDE encountered several challenges within their Active Vibration Isolation system. These included hardware compatibility issues that disrupted system operation, high latency impacting real-time performance, and difficulties in error detection, which resulted in substantial downtime. Additionally, manufacturing defects and debugging delays caused field failures and operational inefficiencies, hindering overall productivity.

To solve these challenges, Epteck develop these solutions.

Customized BSP Development for Hardware Compatibility

Real-Time Linux Integration for Reduced Latency

By enabling real-time Linux, we significantly reduced system latency, improving responsiveness and ensuring efficient real-time processing.

Structured Logging for Improved Error Detection

Early Detection of Manufacturing Defects

Our proactive approach in identifying manufacturing defects led to a 90% reduction in field failures, improving product reliability and minimizing post-production issues.

Benefits Delivered to the Customer

Completed BSP Development

Successfully developed a customized BSP that ensured seamless integration and optimized system performance.

Reduced Latency

Enabled real-time Linux to reduce system latency, enhancing the overall performance of the Active Vibration Isolation system.

Improved Error Detection

99% System Uptime

Resolved hardware compatibility issues and integrated additional peripherals, ensuring high system reliability with minimal downtime.

Early Detection of Manufacturing Defects

IDE’s Experience with Epteck

In-Depth Expertise and Strategic Hardware Support

Epteck assisted with gathering of the requirements for the new hardware platform. And consulted on different solution strategies. Assisted in determining the technology gaps in the current team to support the development of the new IDE product. And they worked on the setup of the build system and supporting infra structure such as firmware update and management etc. for the new product. Kahlil Rashid and his team offered professional, in-depth support, bringing valuable expertise, challenging our hardware supplier, and aiding in the development of the software framework for our new hardware platform.

Hen Hartgers

Project Manager, Aalberts Group (IDE) Germany

Germany

Book a Free Consultation now

Pick a slot

We will connect you with our best Solutions Architect to make sure your project is delivered on time!

- 01 Share your requirements

- 02 Discuss them with our experts

- 03 Get a free quote

- 04 Start the project