Real-Time Manufacturing Intelligence for Modern Textile Factories

Optimize efficiency, reduce waste, and gain total production visibility — from the machine to the operator: StichX is an all-in-one IoT system that empowers manufacturers with RFID-based tracking, real-time analytics, energy monitoring, and automated fault detection.

Make better decisions, faster, and boost productivity by up to 30%.

⭐⭐⭐⭐⭐

Trusted by leading textile factories across Europe & Asia

Why Most Textile Production Lines Are Operating Blindfolded

No real-time production visibility

No traceability across operators or bundles

Manual data = slow, error-prone decisions

Bottlenecks go unnoticed & unaddressed

Energy costs go unmonitored

Limited ERP visibility

Your ERP might track orders — but it doesn’t tell you what’s happening at the stitching unit level.

The harsh truth: most factories don’t know what’s really happening on their floors.

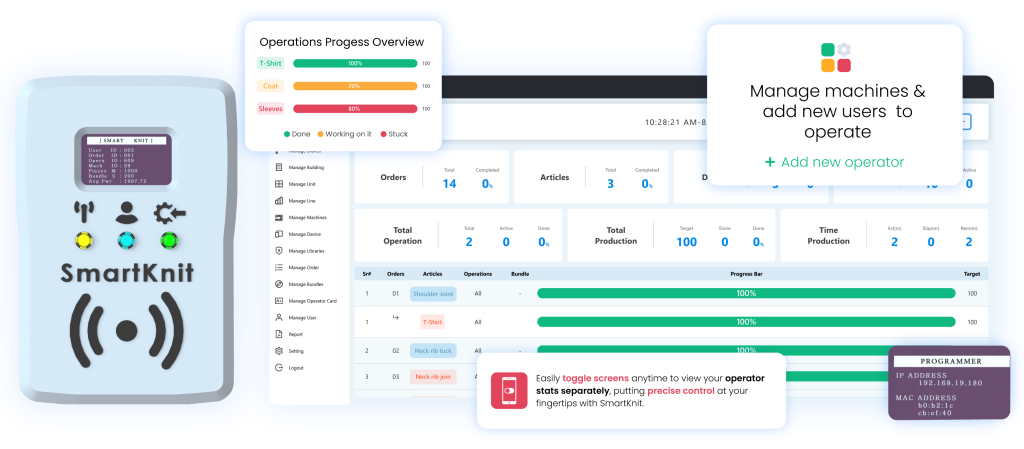

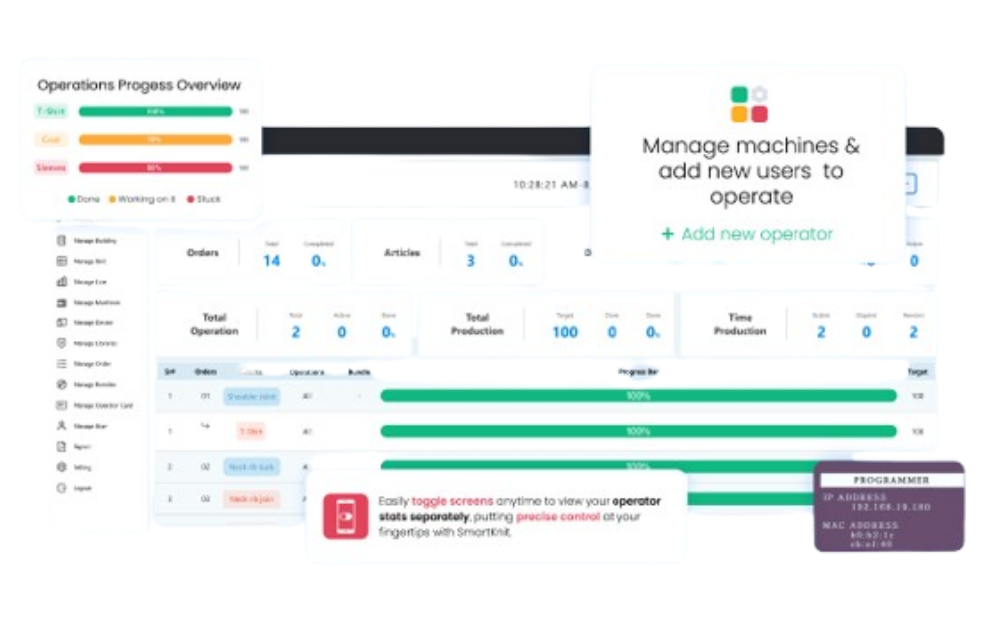

StichX is a plug-and-play IoT system that brings real-time intelligence to your textile manufacturing process.

From operator logins and machine activity to fault detection and energy consumption, StichX captures and analyzes what’s happening on your production floor — automatically. No more guesswork.

No more chasing paper logs. Just clear, actionable insights, instantly.

RFID Cards for Operators & Bundles

SmartKnit Device (Main Module)

Optional Energy Module

Intuitive Dashboard (Web & App)

Everything You Need to Run a Smarter, Leaner Production Line

Feature

Business Benefit

RFID Operator & Bundle Tracking

Eliminate paper logs and errors — trace every bundle to its source

StichX Device

Real-time visibility into machine activity and operator performance

Built for Every Stitch — Trusted Across the Textile Industry

Garment & Apparel Manufacturers

Track operator efficiency, reduce rework, and streamline shift-based reporting with real-time data.

Home Textiles & Furnishing Plants

Ensure consistent output across departments — with multi-style and multi-size control.

Multi-Style Fashion Brands & Exporters

Optimize production lines for different styles simultaneously — with article-level traceability.

OEMs / Contract Manufacturers

Operations Managers & Plant Heads

Stop the chaos. Get predictive alerts and real-time visibility into downtime and delays.

Sustainability & Lean Teams

Measure and reduce energy consumption per order — make every unit greener.

Trusted by Industry Leaders and Proven by Results

SYNTRIC is trusted by leading industrial players for its ability to reduce downtime, improve efficiency, and prevent costly failures.

Fabric Factory Experience

“We used to rely on Excel sheets and handwritten logs. SmartKnit gave us real-time visibility across 30+ machines and reduced our reporting time by 80%.”

⭐⭐⭐⭐⭐

Amir Khan

Factory Manager

TexStyle Garments

Book a Free Consultation now

Pick a slot

We will connect you with our best Solutions Architect to make sure your project is delivered on time!

- 01 Share your requirements

- 02 Discuss them with our experts

- 03 Get a free quote

- 04 Start the project