Reduce Industrial Inefficiencies by 40% with Smart Real-Time Monitoring

SYNTRIC seamlessly connects industrial sensors, provides real-time insights, and automates processes to prevent failures before they happen.

⭐⭐⭐⭐⭐

Trusted by Industrial Clients Globally

Internationally Certified Hardware Product

70% of Industrial Inefficiencies Could Be Prevented with Real-Time Monitoring – Are You Prepared?

Industrial inefficiencies are costing you more than you think. Unplanned downtime costs manufacturers $260,000 per hour on average. 85% of manufacturing executives say they lack real-time visibility into their operations according to Forbes.

Unexpected Equipment Failures

Machines break down unexpectedly → Leading to unplanned downtime & revenue loss.

💰 Cost Impact

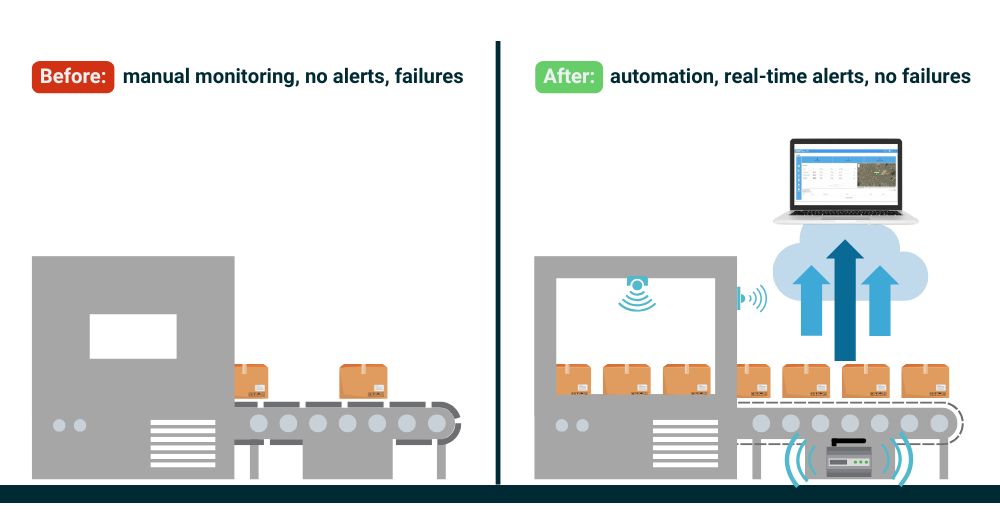

Lack of Real-Time Visibility

Industrial teams rely on manual checks & outdated reports. Delayed responses mean critical failures go unnoticed.

💰 Cost Impact

High Maintenance Costs

Reactive maintenance leads to expensive last-minute repairs. Without predictive insights, companies overspend on unnecessary servicing.

💰 Cost Impact

Lack of Integration Between Systems

Traditional monitoring systems don’t integrate with modern IoT & cloud platforms. Disjointed data makes automation & AI-driven insights impossible.

💰 Cost Impact

Stop Losing Money on Industrial Inefficiencies – Discover How SYNTRIC Solves This

See How SYNTRIC Works! Seamlessly connecting industrial sensors, providing real-time insights, and automating processes.

The Future of Industrial Monitoring is Here – Real-Time Insights, Predictive Analytics & AI Automation

SYNTRIC is an industrial IoT solution that connects, monitors, and automates your operations – giving you real-time insights, predictive maintenance alerts, and full remote control over critical parameters like temperature, pressure, and flow.

Real-Time Monitoring & Alerts

Why it matters

AI-Powered Predictive Maintenance

Uses machine learning to detect anomalies & predict equipment failures

Why it matters

Multi-Device & Sensor Integration

Why it matters

Remote Control & Automation

Why it matters

What Makes SYNTRIC the Best Choice?

- Beyond Basic Monitoring: Most systems only track data—SYNTRIC provides AI-driven insights

- Seamless Industrial Integration: Connects with legacy & modern industrial systems

- Predictive Instead of Reactive: Avoids downtime & unplanned failures before they happen

- Built for Industrial Environments: Robust, secure, and scalable

How SYNTRIC Works – From Data to Action

Seamless Integration, Real-Time Insights, Intelligent Automation: SYNTRIC is designed for effortless deployment and powerful results. In just four simple steps, it connects to your industrial systems, collects critical data, provides AI-driven insights, and automates processes to optimize efficiency and prevent failures.

Connect & Install

Plug SIMOT into your existing industrial infrastructure.

- Installs near machines, pipelines, or facilities

- Connects to sensors, PLCs, and control systems

- Supports RS485, Ethernet, Wi-Fi, BLE, LoRaWAN, GSM

- No need for complex rewiring – integrate and start monitoring

Why it matters?

- Fast deployment Works with existing systems without modifications

- Plug-and-play compatibility Reduce integration costs & time

Collect & Transmit Data

Real-time data acquisition from industrial sensors.

- Monitors temperature, pressure, flow, energy consumption & more

- Transmits data securely to the cloud, on-premise, or local network

- Supports Modbus RTU/TCP, MQTT and HTTP protocols

- Encrypted data transmission ensures cybersecurity compliance

Why it matters?

- Eliminates manual monitoring No more guesswork or delayed responses

- Provides instant visibility Operators & engineers get real-time alerts & insights

AI-Powered Insights & Predictive Analytics

Turn raw data into actionable intelligence.

- Machine learning algorithms detect anomalies & predict failures

- Provides custom dashboards, historical trends & real-time analytics

- Sends automated alerts via mobile app, email, or SMS

- Integrates with SCADA, MES & ERP systems for full automation

Why it matters?

- Prevents costly failures Detects potential breakdowns before they happen

- Optimizes industrial efficiency Helps reduce maintenance costs by up to 40%

Automation & Remote Control

Act on insights instantly—automate responses and optimize performance.

- Triggers automatic shutdowns & safety measures

- Enables remote control of equipment via web & mobile dashboard

- Reduces energy waste & extends machine life with algorithms

- Provides compliance tracking & reporting for regulatory standards

Why it matters?

- Faster response time No need for manual intervention in critical situations

- Improves operational efficiency Reduces downtime & extends equipment lifespan

Industries & Use Cases

SYNTRIC is designed to meet the needs of various industries that rely on real-time monitoring, automation, and predictive insights to improve efficiency and reduce downtime. Here’s where SYNTRIC makes the biggest impact:

Significant Energy Cost Reduction

Achieve measurable energy savings of up to 40%, directly enhancing your profitability.

Minimized Downtime & Maintenance Costs

Real-time monitoring and predictive analytics help prevent costly equipment failures, reducing downtime by up to 30%.

Effortless Regulatory Compliance

Future-Proof Sustainability

Tailored Energy Solutions for Your Industry

Semrise is purpose-built to tackle unique energy challenges across diverse industries. xplore how companies in your sector leverage Semrise for optimized efficiency and profitability.

Manufacturing & Industrial Automation

Manufacturing & Industrial Automation

SYNTRIC provides real-time monitoring of machine health, energy usage, and predictive maintenance alerts to prevent breakdowns

- Reduced unscheduled downtime

- Improved production efficiency

- Better asset utilization

Oil & Gas Industry

Precise fluid flow, pressure, and safety monitoring is critical to prevent costly leaks and failures

Oil & Gas Industry

SYNTRIC integrates with existing pipelines, refineries, and wellheads to monitor pressure, flow rates, and detect anomalies in real-time

- Prevents equipment failures

- Ensures regulatory compliance

- Reduces environmental risks

Water & Steam Monitoring

Water & Steam Monitoring

SYNTRIC ensures accurate, real-time monitoring of water quality, steam pressure, and consumption

- improves resource utilization

- reduces waste

- lowers operational costs

Building Management & HVAC Systems

Building Management & HVAC Systems

SYNTRIC enables smart monitoring of HVAC systems, water flow, and indoor air quality with automated adjustments

- enhances occupant comfort

- reduces energy consumption

- ensures efficient system performance

Trusted by Industry Leaders and Proven by Results

SYNTRIC is trusted by leading industrial players for its ability to reduce downtime, improve efficiency, and prevent costly failures.

Ready to Optimize Your Industrial Operations?

Let’s Take the Next Step!

MCL Experience

“We now have complete visibility into our gas supply chain and have reduced waste by 18%.”

⭐⭐⭐⭐⭐

Tariq Mahmood Babar

Director – MCL

Pakistan

Book a Free Consultation now

Pick a slot

We will connect you with our best Solutions Architect to make sure your project is delivered on time!

- 01 Share your requirements

- 02 Discuss them with our experts

- 03 Get a free quote

- 04 Start the project